WINE ON TAP

A perfect pour every time!

Transforming Wine by the Glass

For bulk wine inquiries, please email HERE

A perfect pour every time!

Transforming Wine by the Glass

Say goodbye to corks! Experience the same amazing handcrafted wines at a substantially lower price. Kegged wine is not only cost-efficient and convenient, but also ecologically friendly. Businesses and consumers alike are enjoying the benefits that premium wine on tap has to offer.

Call a Keg Architect:

Rich – Western WA (833) 946-3534

Therron – Eastern WA (509) 786-3497

Select your wine:

Choose from a variety of red and white wines.

Wow your guests:

Perfect pour every time.

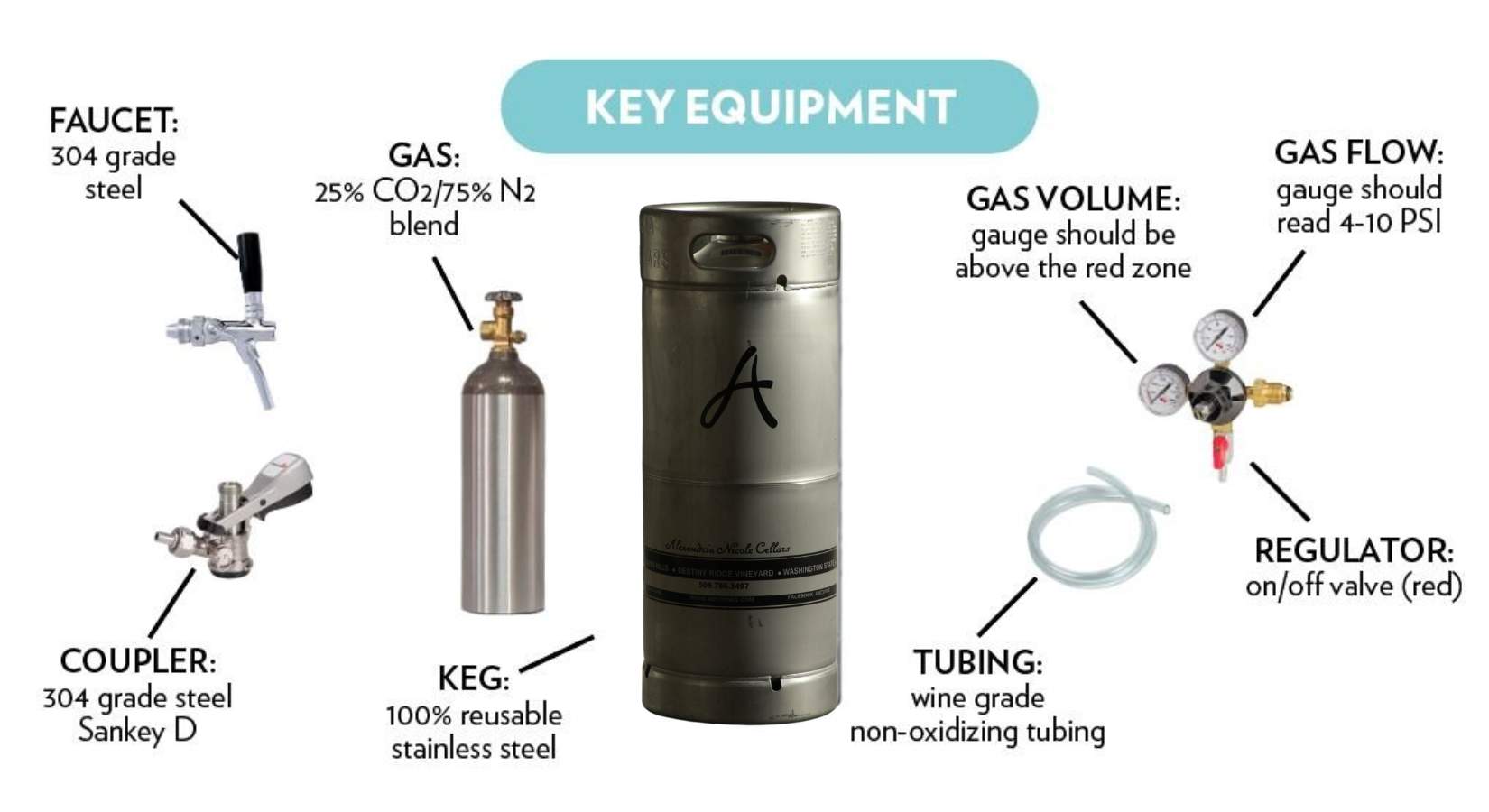

Wine on tap requires slightly different equipment and maintenance than beer on tap.

Below are some easy tips and tricks to help you serve the best tasting and sustainable glass of wine.

Any metal that comes in contact with the wine needs to be 304-grade stainless steel.

Tubing: Wine grade non-oxidizing tubing.

Faucet: 304-grade steel

Gas: Blended 25% CO2 / 75% N2 Beverage Gas(Guinness Gas)

The gas volume gauge should read above the red zone

Tubing: XtraFlexmaste non-oxidizing tubing

Faucet: 304-grade steel, flow-control faucet

Gas: 100% CO2 | gas volume gauge should read above the red zone

Ensure every pour is the perfect pour.

Gas Pressure: 4 – 10 PSI

Temperature: 40 – 45°

Gas Pressure: 4 – 10 PSI

Temperature: 55 – 60°

Gas Pressure: 12-14.5 PSI

Temperature: 34-36°

Store untapped kegs with other wines at room temperature.

The wine will stay fresh for three months when tapped and 12 months untapped.

The system should be cleaned quarterly or at the change of product.

Wine not pouring? Wine pouring too fast or too slow? Try these easy fixes.

Confirm the gas tank is turned on: screw the valve at the top & check that the red valve is open by

confirming it is in line with the gas line.

Next, check the reading on the lower-left gauge. If it’s in the red zone, it’s time to change the tank.

Lift the keg to see how heavy it is. If it feels empty, it’s time to change your keg.

To adjust the flow, locate the regulator attached to the gas and check the upper gauge (0-60 psi).

Using a flat-head screwdriver, twist the screw to the right to increase flow and twist to the left to decrease flow.